Air compressor test bench

1. Equipment Use

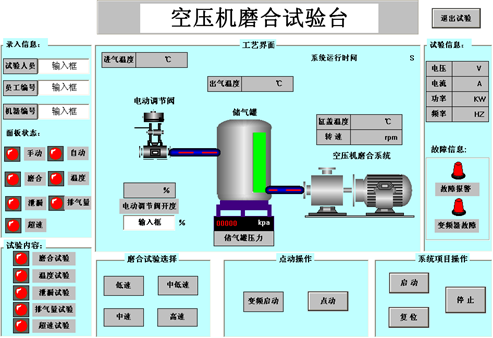

The air compressor test bench is used for functional testing and running-in test of the air compressor on the subway vehicle. Including running-in test, air volume test, leak test, temperature test and overload test.

2. Main Functions

1) Perform the running-in test on the air compressor after inspection: set the speed and running-in time, and complete the running-in of each speed segment in turn according to the setting procedure. The running-in time and each speed value can be manually set.

2) Exhaust gas test on air compressor: The flow test range meets the transport flow requirements of Wuhan Metro air compressor. The current, voltage and power of the air compressor are measured while measuring the displacement.

3) Test of exhaust temperature and exhaust humidity of air compressor: The temperature and humidity of the dryer exhaust port are measured by the temperature and humidity sensors.

4) Sealing performance test on air compressor: air compressor should not have any leakage.

3. Main structural composition

The equipment is mainly composed of measuring and controlling platform, pneumatic system, inverter control system, temperature sensor transmission system, pressure sensor transmission system and electric signal processing system.

4. Main Technical Parameters

|

Air compressor characteristics and technical parameters |

||

|

Reference condition |

||

|

1 |

Air inlet pressure |

1 bar(a) |

|

2 |

Air inlet temperature |

20℃ |

|

3 |

Working pressure |

9.5 bar(e) |

|

4 |

Motor speed |

1470 rpm |

|

5 |

Type of lubricating oil |

Roto-H |

|

Operational limitation |

||

|

1 |

Maximum working pressure |

10 bar(e) |

|

2 |

Minimum working pressure |

4 bar(e) |

|

3 |

Minimum ambient temperature |

-25℃ |

|

4 |

Minimum ambient temperature |

-40℃(with a heating device of –40℃) |

|

5 |

Maximum ambient temperature |

50℃ |

|

6 |

Maximum storage temperature |

70℃ |

|

7 |

Relative humidity |

0-100 % |

|

8 |

Direction of movement |

Any direction |

|

Performance data |

||

|

1 |

Traffic FAD |

17.5 l/s |

|

2 |

Sound pressure level SPL at 4.6 m open space |

67 dB(A) |

|

3 |

Outlet oil content |

3 mg/m3 |

|

4 |

Motor Power |

11kw |

|

5 |

Nominal current |

21.5A |

|

6 |

Starting current |

133.3A |

|

7 |

Motor efficiency |

88.5% |

|

Design data |

||

|

1 |

No. of compression stage |

1 |

|

2 |

Cooling air flow |

16.7 m3/min |

|

3 |

Safety valve setting |

11.5 bar(e) |

|

4 |

Outlet pipe diameter |

?’G |

|

5 |

Weight |

237kg (hoisting) |

|

6 |

Length |

1265mm (hoisting) |

|

7 |

Width |

665mm (hoisting) |

|

8 |

Height |

506mm (hoisting) |

|

Equipment technical parameters |

||

|

1 |

Pressure measurement range |

0 to 1.2 MPa (outlet pressure range) |

|

2 |

Pressure measurement accuracy |

0.25% FS |

|

3 |

Rated power consumption |

About 10 kW |

|

4 |

Flow test range |

0.8~1.2m3/min |

|

5 |

Speed adjustment range |

0~3000rpm |

|

6 |

Inspiratory temperature measurement range |

-10℃~+45℃(±0.2℃) |

|

7 |

Inhalation humidity measurement range |

0~90%、±0.2% 90~100%、±0.3% |

|

8 |

Dryer outlet temperature measurement range |

0~150℃、±0.2℃ |

|

9 |

Dryer outlet humidity measurement range |

0~90%、±0.2% 90~100%、±0.3% |

|

10 |

DC power supply |

DC 150 (±30%) V adjustable (for air dryer power supply) |

5. Equipment pictures

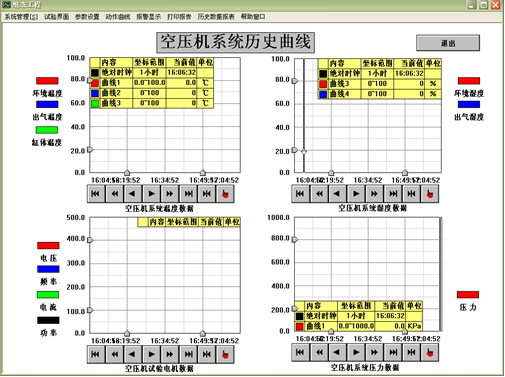

6. Device software interface